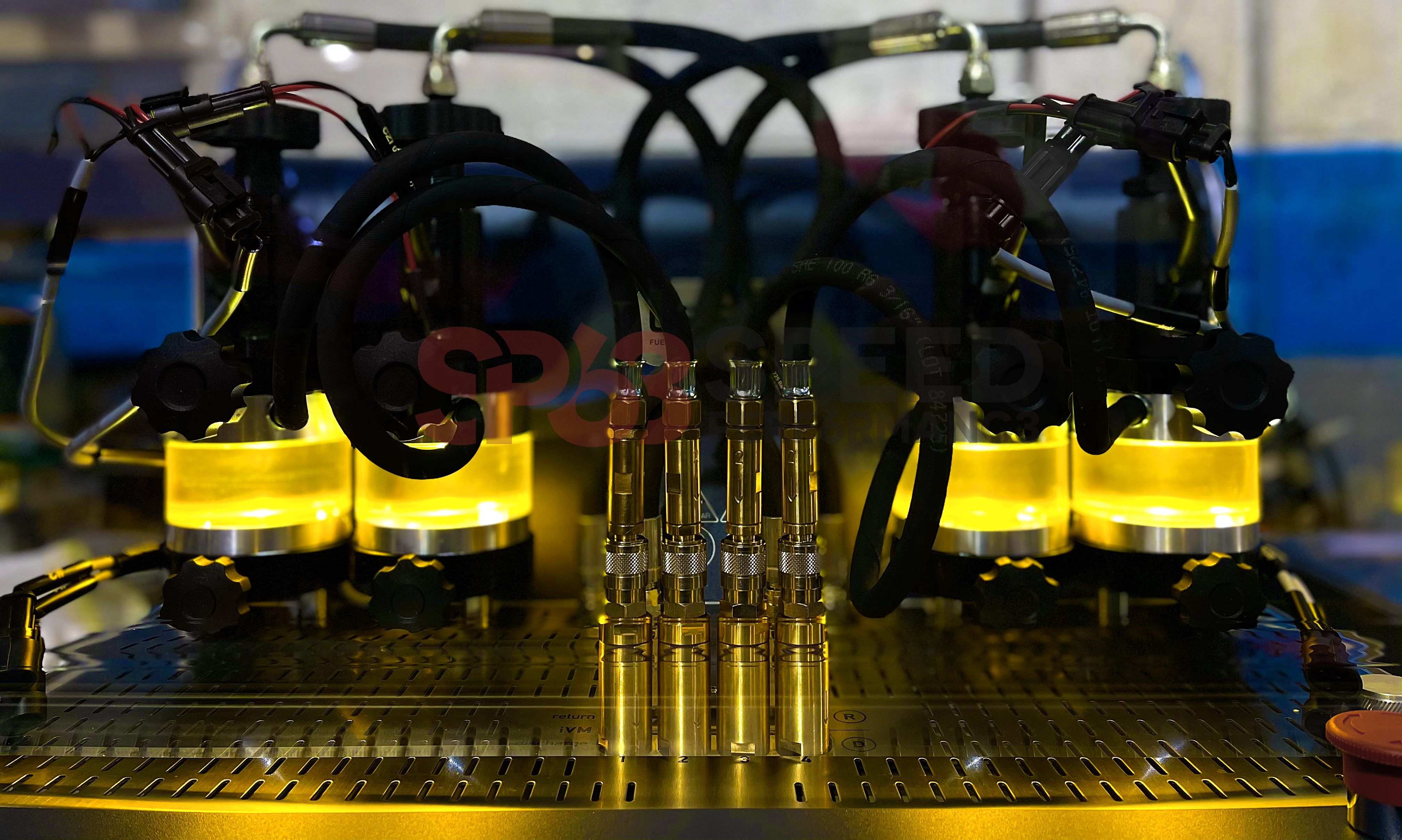

Gasoline direct injection requires high pressure testing to truly diagnose operation faults. Speed Perf6rmanc3 once again provides the only complete testing solution in the market today, with the Revolutionary GDU.4r and GD1r Test benches.

Below is a description of the various tests we perform when flow testing your DI Injectors using our state of the art GD1R Flow Bench. We use two separate pieces of equipment. The GD1R Flow Test Machine is used to measure all the flow characteristics of your DI Injector and a seperate machine is used for ultrasonic cleaning. We will continuously clean each and every injector until it passes ALL TESTS with the GDU.4R and the injector meets OEM specifications as it would if the injector was new.

We service all makes and models!

R2LC - The R2LC Test is performance to check the impedance of the injector and make sure it is within OEM Specification

- Electrical test for k/F, /H

CFL - The CFL test is performed to test the injector for any fuel leakage both internally and externally while under pressure with the injector OFF.

- Check For Leaks test (injector internal or external)

NLT - The nozzle leakage test is performed to check that the injector doesn't leak fuel out for the nozzle tip while under pressure and injector is OFF. This test is done to see if you have what is stereotypically called "a leaking injector"

- Nozzle Leakage Test @High Pressure

iVM (FL, PL, EM, LL, PI) - The iVM test is performed under various conditions such as full load, part load, etc. and is used to verify that the injectors flow rate and charactersitcs are within OEM Tolerances under all known conditions.

- Injector Volume Measuring test (full-load, part-load, emissions, low-load, pre/post-injection tests and more…)

RSP - This test measures the fuel injector nozzle's response time (how long it takes for the nozzle to open when an electrical charge is applied) and that it meets OEM Spec.

- Injector nozzle Response-time test

SPR - This test is performed to ensure the injector's spray pattern has no abnormalities and that the shape of the spray pattern is how it should be when new.

- Dynamic Spray test performed in all testing conditions

Features of our GDU.4R/GD1R Test Bench:

iPSC

- Illuminated Pressurized spray chamber

- View of injection pattern up to 1000Bar

- Visually diagnose NOP, incorrect spraying, leaky / seized injectors

Reports

- Easy fail-track color report for each injector.

- Single-page Quick report or Multi-page Analytic reporting

Injection Services Apply to:

- Direct Injector

- Port Fuel Injector

We also replace the OEM Filter with stainless Steel filter